- Routine & Preventive Maintenance

- Trouble shooting Corrective Maintenance

- Shut-down Maintenance

- Turn-Around

NSK Electric Services Team (EST) follow Comprehensive Method Statement (CMS) that is usually used in the field to determine the condition of an Electrical power system. CMS can form the basis for a comprehensive Electrical Preventative Maintenance (EPM) program; however, they are not intended to be a mandatory practice or applicable and all-inclusive for each type of equipment found in modern electrical power distribution systems. This CMS should only be performed by persons that are qualified by experience and training in the proper and safe execution of EPM. In lieu of a customer specification or other written guidelines, our Standard Operating Procedures (SOP) explained the inspection and testing procedures that NSK Electric Services Team (EST) should follow while performing maintenance testing of electrical equipment.

Operation & Maintenance of AIS Switch Gears (MV & LV) equipped with VCB's, OCB's , ACB's , Power, Distribution & Rectifier Transformers , LT & HT Motors ; Diesel & Gas Engine driven Turbo Generators, Automatic Transfer Switches-ATS , Variable Frequency Motor Drives-VFMD,PLC Controlled Equipment, Batteries & Chargers, Microprocessor controlled UPS System O/H Crane ,Heat Trace System, Conveyor system, Cathodic Protection, Fire alarm system, Public Address system MOV's and Protective relays(Electromagnetic, Static & Microprocessor-based) of Electrical equipment.

- Operation, Maintenance , Troubleshooting , Repairing of HV/MV/LV Power, Distribution & Rectifier Transformers, and associated Instrument Transformers & Accessories.

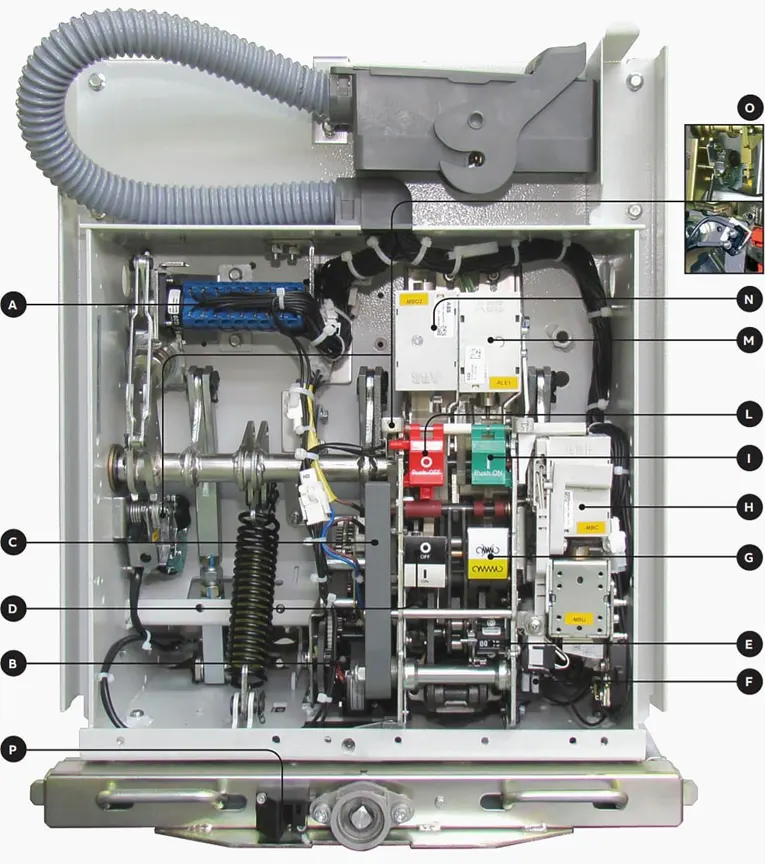

- Switching Operation & Maintenance of HV/MV/LV Switch Gears & Circuit breakers equipped with SF6 CB's, ABCB's, VCB's, OCB's, MOCB's & ACB's.

- Maintenance, Overhauling of LT and HT Induction Motors for driving of Pumps, Compressors, Blower Fans with plant utilization up to 11KV.

- Switching Operation & maintenance of Medium/Low Voltage (MV/LV) network Power distribution Switchgears & Control gears assembly equipped with VCB's, OCB's , ACB's , MCCB & ELCB , MCB, RCCB, SPD, disconnectors & load break Switches , Contactor &Relays ,Protection & Monitoring equipment and control gears.

- Operation, Maintenance , Troubleshooting of Diesel Engine driven Emergency Generators and Control Panel equipped with Automatic Transfer Switches-ATS to the Essential feedings

- Operation, Maintenance , Troubleshooting and Repair of Microprocessor Controlled AC/DC UPS System to the Vital feeding to the critical process & Substation equipment.

- Maintenance of of S/S Fire alarm system, Fire Suppression System, HVAC, Air Purging System

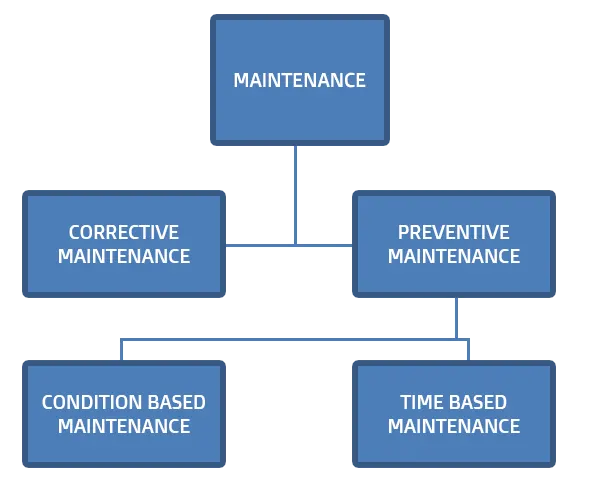

Why is maintenance so important?

- The Primary purpose of transformer maintenance is to ensure the internal & external parts of the transformer and accessories are kept in good condition and " fit for purpose " and able to operate safely at all times. A secondary and equally essential purpose is to maintain a historical record of the condition of the transformer.

- Transformer maintenance can be done periodically or as condition-based maintenance. The later is usually the most economical way of doing maintenance.

- Recommended maintenance are then done based on one or more of the following: inspections, analysis of oil samples, electrical measurement, testing of equipment, measurement of temperatures by using a heat sensitive camera, monitoring (off-line and /or on-line ).

Condition monitoring

- Condition monitoring equipment that can be used to extend the life of a transformer or to prevent catastrophic could pay for itself many times over. However, condition monitoring does not come free of charge, and tight budgets are to be met.

- Life-cycle costing must be applied. This comes from the summation of installation, maintenance, repair and operation cost. Several options of monitoring equipment covering a wide spectrum of cost are available or are in development.

- Monitoring equipment looking at one or two specific parameters is really available on the market at relatively low cost. At the other end of the cost spectrum, not only can many parameters be monitored, but also an expert system or artificial intelligence capable of generating a estimate of the overall plant condition will interrogate the data.